Sensational Tips About How To Build Turbo Charger

In this video, the boys from mighty car mods show you in 5 minutes whats involved in turbo charging your car.

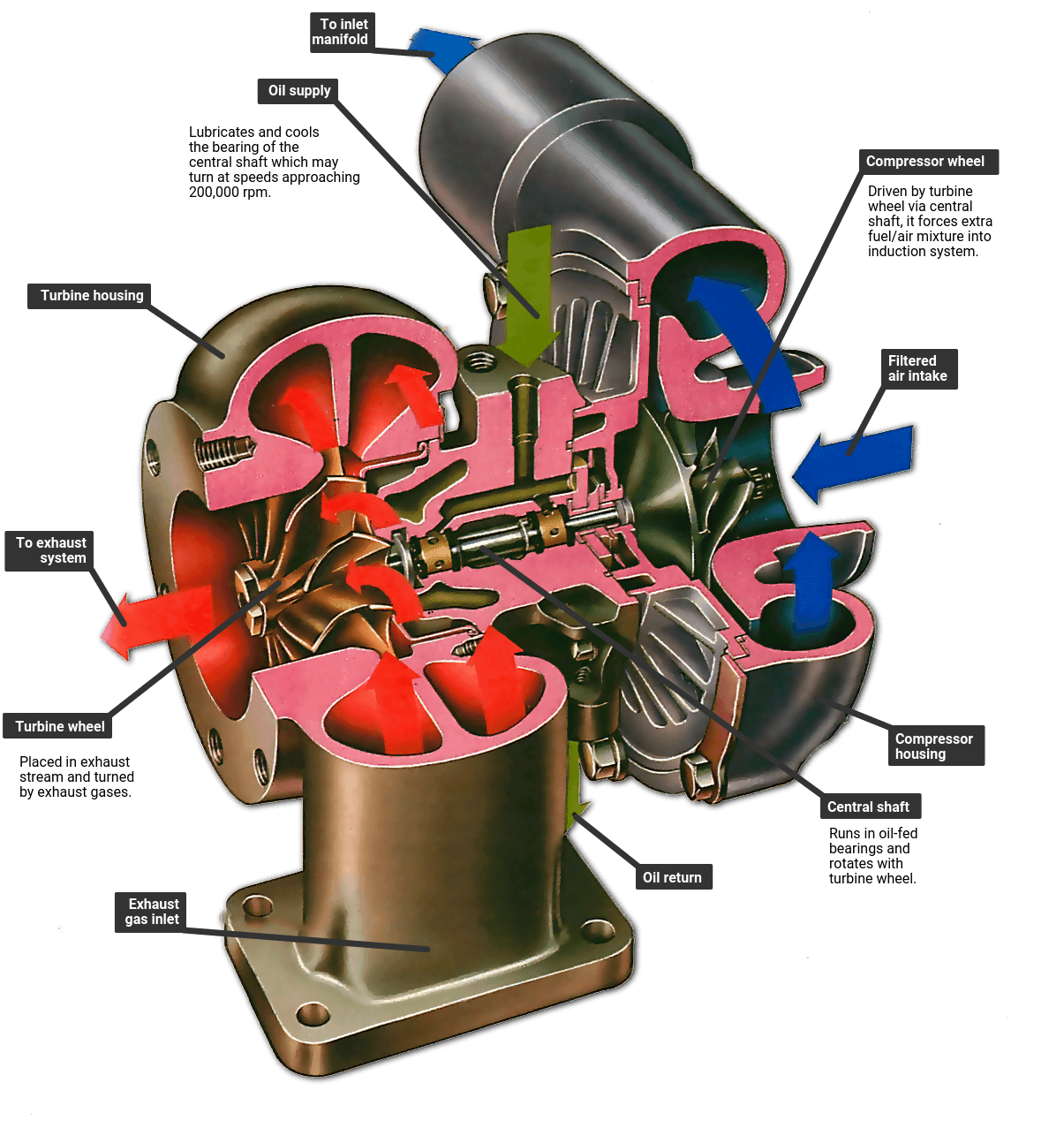

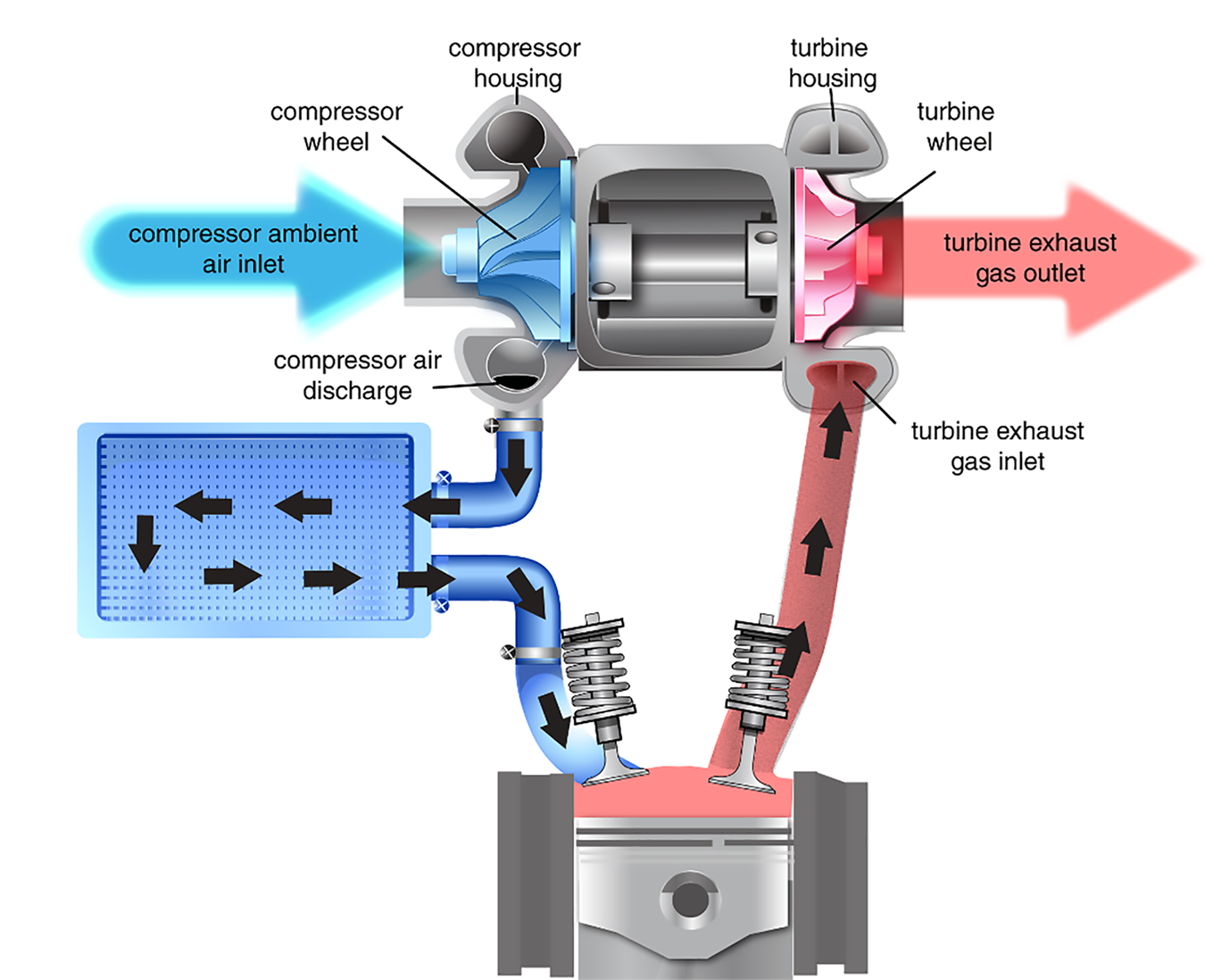

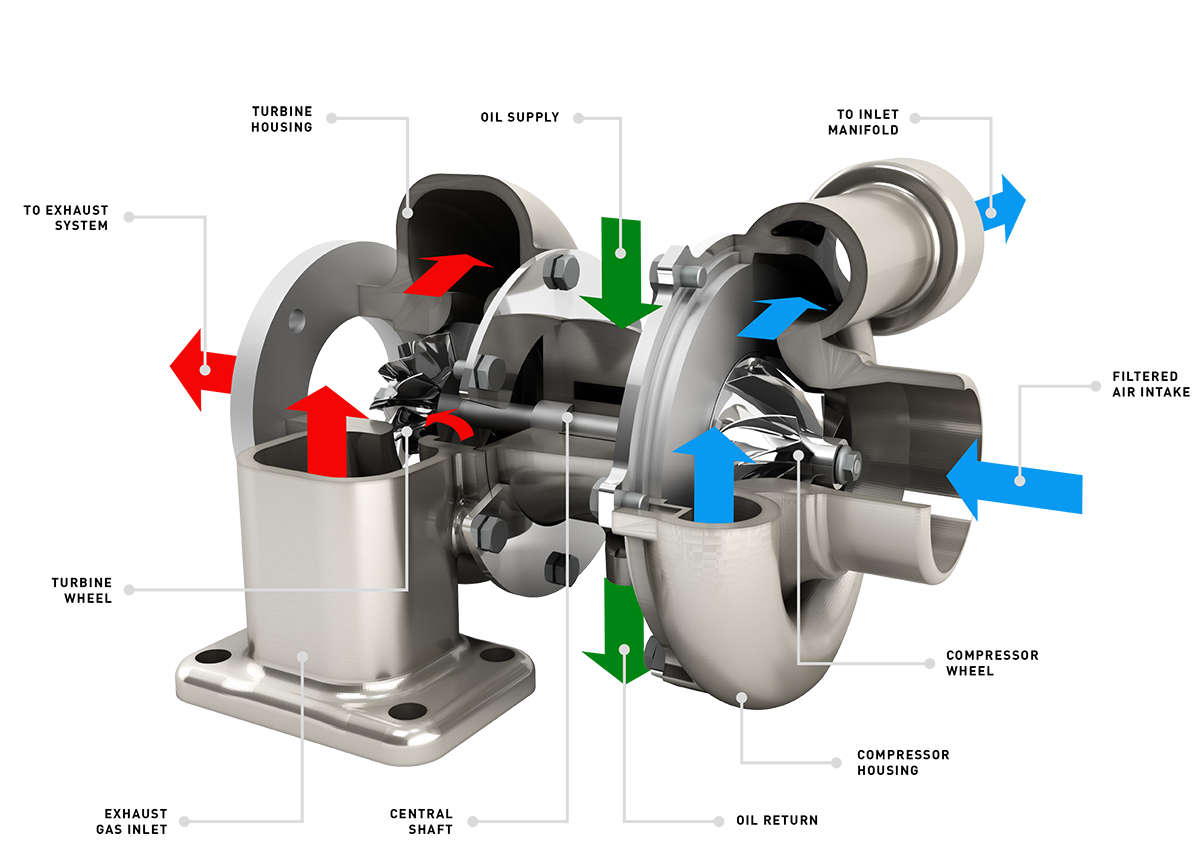

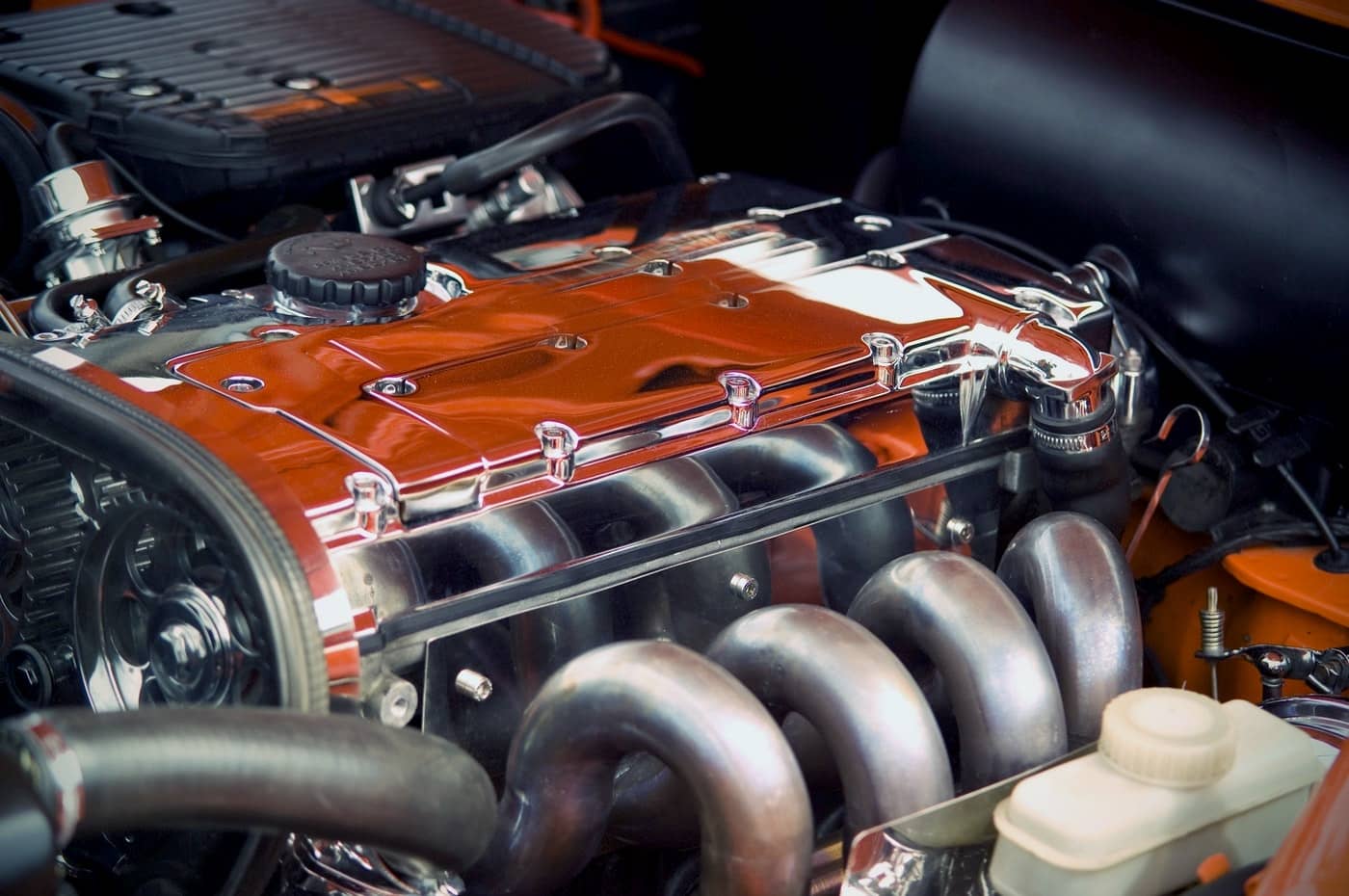

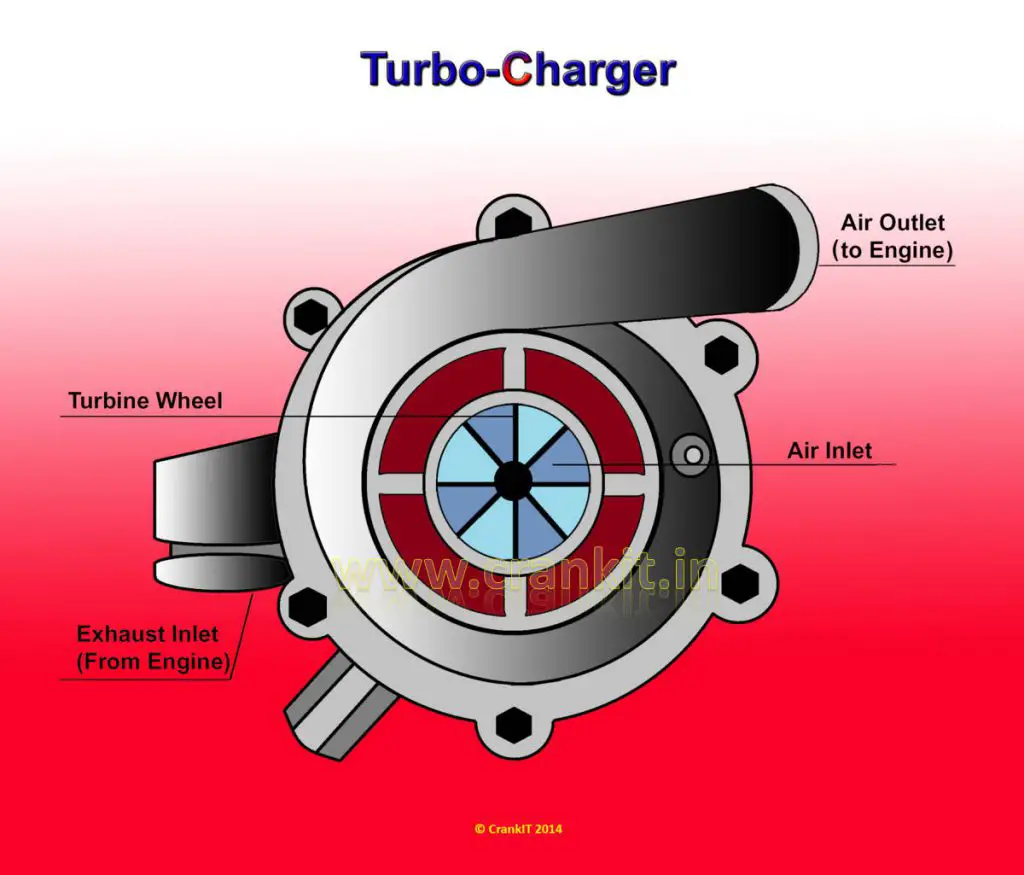

How to build turbo charger. The turbine, the compressor, and the bearing system that supports the. Turbochargers are a type of forced induction system that compresses the air flowing into the car's engine. The main components of the turbocharger are:

This guide will teach you to design, test, install, and maintain. Step 2 fold the paper into fourths make a half fold in. Turbochargers are built using materials with mechanical strength and thermal resistance to withstand high rotational speeds, extreme temperatures, and.

With the turbocharger forcing much more air into the engine than expected by the ecu, the air/fuel ratio will be severely lean, likely leading to detonation, in which. While that sounds good in theory, it can lead to. Two turbos, new computer software, and a lot of forethought

Like other forced induction devices, a compressor in the turbocharger pressurises the intake air before it enters the inlet manifold. Scissors (modifications only) pencil step 2: So, while complete turbo kits aren’t as plentiful as the range of supercharger systems, they can be created by essentially running enough tubing between the basic.

1 piece of 8.5 by 8.5 inch paper tape optional: This is a video for people who are interested in machining their own turbo not very interesting but you could put some compressed air up to it and makes a lo. In the case of a turbocharger, the compressor is powered by the kinetic energy of the engine's exhaust gases, which is extracted by the turbocharger's turbine.

After it does, it can create an instant engine boost. The advantage of compressing the air is that it lets the. Unlike a traditional turbocharger, which uses exhaust gasses to spin itself up, electric turbos utilize an electric motor (the compressor is also electric).